DfOSH-CMI web-based tool

Author: Patrick Manu (Mechanical, Aerospace and Civil Engineering)

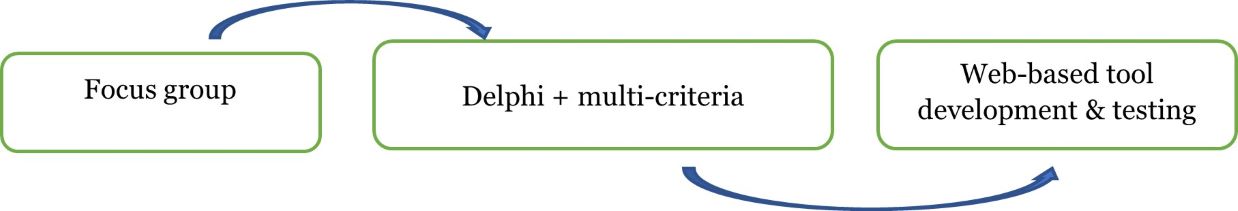

The UK construction sector is notorious for a high prevalence of occupational injuries and illnesses. The design of buildings/structures is a significant contributor to the occurrence of these tragedies. Consequently, through the practise of ‘design for occupational safety and health’ (DfOSH), designers (e.g. architects and engineers) when preparing or modifying designs, are expected to eliminate, reduce or control foreseeable safety and health risks that may arise during construction. This brings to the fore the challenge of industry stakeholders understanding the capability of design firms to practise DfOSH. The research aimed to develop a web-based DfOSH capability maturity indicator (DfOSH-CMI) tool for the construction sector. DfOSH-CMI provides a mechanism for profiling the DfOSH capability of construction organisations with design responsibilities in order to pave way for improvements in DfOSH capability and practice. The research design involved: focus group; Delphi survey; and web-based tool development (Figure 1). The focus group helped to identify organisational attributes that determine DfOSH capability. Subsequently, the Delphi was applied in conjunction with a multi-criteria decision making technique (i.e. voting analytical hierarchy process) to quantify the weight/importance of the attributes. The attributes together with their weight were used in the development of the DfOSH-CMI web-based tool.

Applying open research practices

Co-production was central to the DfOSH-CMI project in order to ensure the practical utility of the research outcomes. The co-production element included:

- Project conception: During proposal development, several informal discussions were held with relevant stakeholders in the construction industry in order to better understand the industry challenges/issues and what manner of solutions would be appropriate. Through these discussions the research proposal received the support of 10 partner organisations (construction client (1 no.), contractor (2 no.), designer (2 no.), OSH consultant (2 no.) regulatory agency (1 no.), and academic institution (2 no.)) which represented the spectrum of key stakeholders who are concern with DfOSH practice. The discussions also shaped the focus of the proposal.

- Project execution: The project partners constituted a project advisory group. As per the research approach, three iterations of focus group discussions were held with the industry project partners in order to identify the organisational attributes that determine DfSOH capability (e.g. competence of staff and organisation’s top management commitment). Subsequently, the industry partners through their networks facilitated the assembly of a large panel of experienced industry experts (over 30 no.) for the Delphi technique, which involved three rounds of survey. Prior to the Delphi survey, the industry partners reviewed the questionnaire and tested it in a pilot administration. During the tool development stage, the industry partners were invited to test an initial version of the tool. Based on their feedback, the tool was modified before a wider industry testing. During the wider industry testing, the industry partners played a key role in disseminating to testing protocol to their network of organisations to ensure the receipt of insightful and constructive feedback.

- Project close: During the closing phase of the research, three industry engagement and dissemination seminars were held in different UK locations - Bristol, London and Manchester. Each event was well attended by a broad spectrum of the key industry stakeholders who provided feedback on the tool and future work.

Overcoming challenges

From the very onset of the project, the fragmented nature of the construction sector (characterised by different project actors) presented a challenge in terms of obtaining the ‘buy-in’ of the main category of stakeholders. This challenge was tackled from project conception through the invitation of major industry players and academics who subsequently formed the project consortium and advisory group. Having a large consortium, however, posed the challenge of managing their views and interests, which sometimes were divergent. The multiple iterations of the focus group was useful in addressing this by way of enabling dialogue and refinement of ideas and concepts. Furthermore, the leadership and interpersonal skills of the principal investigator in conjunction with support by senior established researchers acting as academic advisors, enabled the challenges to be addressed.

Benefits of using these open research practices

The use of co-production was highly commended by the independent reviewers of the proposal, who rated the proposal very highly. Also, co-production ensured the relevant ‘ingredients’ of the DfOSH-CMI tool were captured and incorporated in its development. Finally, the co-production raised the profile of the research among industry stakeholders, which eventually led to winning a competitive innovation award.

Top tip

Successful co-production stands to benefit from: (1) early involvement of the key stakeholders (possibly as project partners at the proposal development stage); (2) providing regular updates to the key stakeholders including shouting about impact stories along the research journey in order to keep them enthused; and (3) leveraging stakeholder/partner network for wider interaction with the research audience.